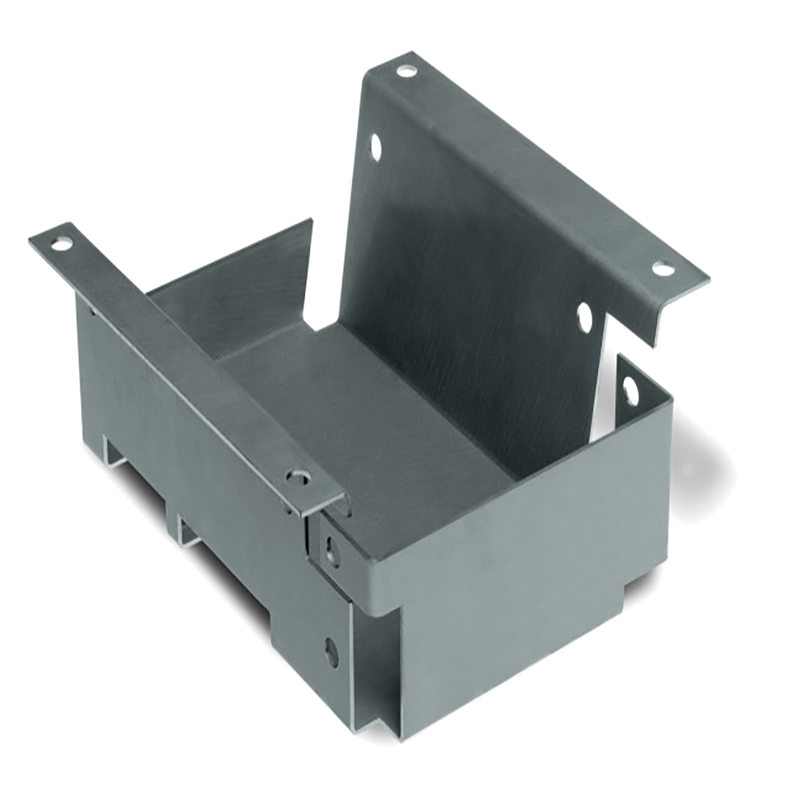

Custom Sheet Metal Fabrication

Sheet Metal Fabrication Services

Welcome to RFS, your trusted partner for all things sheet metal fabrication. With nearly 20 years of service experience, we have built a reputation for delivering quality results and exceptional customer service.Our team of skilled craftsmen and engineers are dedicated to bringing your vision to life, no matter the size or complexity of your project.

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat sheets of metal into complex shapes through a combination of cutting, bending, and forming techniques. This involves the use of specialized tools, such as punch presses, laser cutters, and press brakes, to turn flat sheets of metal into products like car body panels, metal enclosures, or ductwork. The sheet metal can be made from a variety of metals, including steel, aluminum, brass, and stainless steel, and the fabrication process can vary depending on the specific requirements of the end product.

At RFS, we offer a wide range of solutions for sheet metal processing services, including laser cutting, punching, bending, welding, and finishing. Our state-of-the-art equipment and experienced technicians ensure that every project is completed with precision and accuracy. In terms of raw materials, we work with a variety of metals including steel, aluminum, brass, and stainless steel to ensure the highest quality end products. Our team is dedicated to providing comprehensive support, from product design and development to delivery, to ensure that each project is a success. Whether you need a simple metal component or a complex, multi-part assembly, RFS has the expertise to provide the best solution for your needs.

Leading sheet metal fabrication supplier, Since 2000!

RFS has been engaged in custom metal fabrication for decades and has accumulated extensive project experience.Our factory production line has passed the ISO 9001:2015, and the high-quality workmanship has also been highly recognized. With the increasing demand for custom metal manufacturing business, we have expanded the plant accordingly to reduce production costs and improve production capacity and efficiency. The current plant area has covered 50,000 square feet, which can easily handle the mass production of various types of workpieces.

Today, as a leading sheet metal manufacturing supplier, RFS has provided extensive services for various industries, such as aerospace, medical equipment, industrial equipment, mechanical equipment, etc. We possess enough experience and professional ability to handle your project.

Sheet Metal Fabricationm Services Available at RFS

Laser Cutting

RFS provides exceptional laser cutting services, utilizing advanced equipment and experienced technicians for precise and efficient cuts. From small parts to large components, we deliver high-quality results with accuracy on every project.

CNC Machining

RFS offers top-notch CNC machining services with the latest technology and expert technicians. From prototyping to production runs, our CNC machining capabilities cover a wide range of materials and industries, providing accurate and efficient results every time. Choose RFS for all your precision machining needs.

Welding Services

RFS's welding services are focused on providing high quality welding and metal fabrication solutions. We offer a wide range of welding technologies, including TIG, MIG and stick welding, to meet the needs of a variety of metal products. Our services include metal fabrication, repair and maintenance, custom welding and more. We are known for our attention to detail, prompt delivery and cost effective solutions.

Metal Bending

RFS’s metal bending services specialize in the process of shaping metal materials into desired shapes and forms using specialized machinery. We offer a range of services that include bending, forming, rolling and welding of a variety of metals including steel, aluminum and stainless steel. Our goal is to provide high quality, precise bending solutions that meet the specific needs of our customers.

RFS Sheet Metal Manufacturing Capabilities

| Processable size | 10' x 20' (3.05 m x 6.10 m). Larger part volumes are available upon request. |

| 7 working days | Row 2, Content 1 |

| Plate thickness | 0.024" - 0.250" typical. Thicker or thinner sizes are available upon request. |

| General Tolerance | +/- 0.010" for single plane or flat parts with edge-to-edge, edge-to-hole, and hole-to-hole features; +/- 0.010" bend-to-edge/hole feature For multi-planar bent parts, +/- 0.030" for hole-to-hole/edge, edge-to-edge, and overmolded parts; +/- 1 degree bend angle. |

| Punching | 2″ diameter hole capacity, or larger upon request |

| Welding | Weld edges and seams, weldments and assemblies |

Sheet metal materials provided by RFS

Stainless steel 301

Stainless steel 304

Stainless steel 316/316L

Learn more about stainless sheet metal.

Steel 1018 (Low Carbon)

Learn more about steel sheet metal.

Available Sheet Metal Finishes

RFS offers a variety of sheet metal finishes to meet the specific needs and preferences of our customers. Our available finishes include.

A protective zinc coating used to prevent corrosion.

A durable and long lasting finish that can be applied in a variety of colors.

An electrochemical process that forms a protective oxide layer on the surface of aluminum.

A traditional painting process that provides a smooth and uniform surface.

A process that improves the surface finish of stainless steel, providing a mirror-like appearance.

Each finish option has unique benefits and properties, and RFS can work with customers to determine the best finish to meet their specific requirements. RFS is committed to providing high quality finishes that not only look great, but provide long-lasting protection for sheet metal products.

Advantages of Sheet Metal Fabrication

Cost-effectiveness

Sheet metal fabrication is a cost-effective method of producing high-quality metal products in large quantities.

Versatility

Sheet metal can be fabricated into a wide range of shapes, sizes, and designs, making it suitable for a variety of applications.

Durability

Sheet metal products are strong, resistant to wear and tear, and can last for many years with proper maintenance.

Customization

Sheet metal fabrication allows for custom design and production, making it possible to create unique and specialized products.

Precision

With advanced technology and equipment, sheet metal fabrication offers precise and accurate cutting, bending, and shaping capabilities.

Ease of Recycling

Sheet metal products can be easily recycled and repurposed, making it an environmentally friendly choice.

Overall, sheet metal fabrication is a versatile, cost-effective, and efficient method of producing high-quality metal products that can meet the specific needs of different industries and applications.

Sheet Metal Applications

At RFS, we provide a wide selection of metal fabrication services that are customized to the specific requirements of your projects. And we have the ability and confidence to meet different customers’ needs, which has successfully brought cooperation to us with companies across various walks of life, including but not limited to medical, construction,food processing equipment, aerospace, agriculture equipment, automotive and numerous others.

Automotive

Sheet metal is used in the manufacture of automotive bodies, panels, and parts.

Medical

Sheet metal is used in the manufacture of medical equipment and devices, such as surgical tables and hospital beds.

Aerospace

Sheet metal is used in the manufacture of aircraft structures, such as fuselages and wings.

Construction

Sheet metal is commonly used in construction for roofing, cladding, and flashing.

Food and beverage

Sheet metal is used in the manufacture of food and beverage processing equipment, such as storage tanks, mixers, and conveyors.

Agriculture

With more than 15 years of rich experience in manufacturing agricultural equipment metal parts...

Why Use RFS's Sheet Metal Fabrication Services?

Expertise

With a team of experienced technicians, RFS has a deep understanding of sheet metal manufacturing processes and technologies. This expertise allows us to provide high quality and efficient service to our customers.

Quality Control

RFS implements strict quality control measures to ensure that all products meet or exceed industry standards and customer expectations.

Customization

RFS offers custom design and production services that make it possible to create unique and specialized sheet metal parts.

Extensive Capabilities

RFS has the ability to manufacture a wide variety of sheet metal parts, including those made from steel, aluminum and stainless steel. We also offer a variety of surface treatments and coatings, making it easy to find the right solution for a specific application.

Competitive pricing

RFS is committed to providing high quality sheet metal parts at competitive prices. We work with our customers to find cost effective solutions to meet their specific needs and budgets.

Choosing RFS’s sheet metal parts provides customers with a team of experienced technicians, stringent quality control measures, extensive capabilities, customization options, and competitive pricing. These factors make RFS a reliable and trustworthy choice for sheet metal fabrication services.