Auto CAD Detailing

首页 » Metal Fabrication Services » Auto CAD Detailing

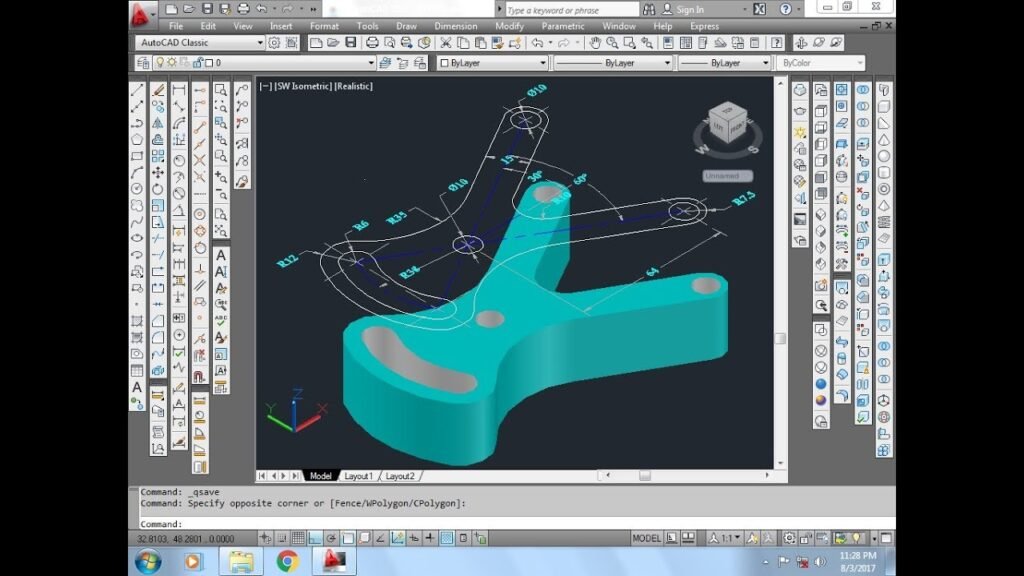

Auto CAD detailing service

At Zehan, we have decades of design and project experience. Our technicians have received strict training and are proficient in using AutoCAD software. Our factory is also equipped with corresponding advanced equipment.

According to the product specifications and any sketches you provide, we will use AutoCAD to create the 3D design details of the product required by your metal fabrication project, and then send the details back to you for inspection, modification and final confirmation before putting into production.

Eventually, we will accurately and effectively invest in the subsequent metal manufacturing for your project with the help of CAD details, making your products from design to reality.

What is Auto CAD detailing

AutoCAD is an automatic computer-aided design software for 2D drawing, detailed drawing, design documents and basic 3D design.

It has become a widely popular drawing tool around the world. It’s generally used in industrial drawing, engineering drawing, civil construction, electronic industry and many other fields.

AutoCAD detailing is to use this software to draw detailed drawings for various projects, usually in 2D or 3D form, so as to promote the transformation of project results

Benefits of AUTO CAD DETAILING

1.High Productivity

AutoCAD can efficiently create 3D model drawings for the project of metal parts, reducing the workload for engineers, saving time and has considerable repeatability, which can greatly improve the productivity of metal parts.

2.High Precision

Compared with traditional manual drawing, under the supervision of engineers, CAD drawing is almost error-free, with higher accuracy and accuracy.

3.Secure Storage

AutoCAD software supports the safe storage of design data, and will create a database for drawings. All changes you make to drawings will be recorded, so there is no need to worry about the loss or damage of data.

4.Low Error Rate of Production

The detailing of metal parts drawn by AutoCAD can display the products in detail and intuitively, promote product visualization, enable engineers to quickly understand the product design, facilitate identification and resolution of problems in the design before entering the production process, and reduce the production error rate.

5.Cost Optimization

AutoCAD detailing can be shared among teams so that they can view it at any time and easily modify in a timely manner, which can not only save construction costs and time, but also reduce economic losses caused by engineering mistakes.

Advantages of our services

Professional Team

Our team possesses professional knowledge and ability. If you need, we will provide optimization suggestions for your project design and ensure that your project is professional and accurate.

Abundant Experience

Our experts handle thousands of projects every year, thus they are fully equipped with the professional knowledge to design detailing and manufacture metal parts for your project.

Quality Assurance

Our engineers are proficient in the use of AutoCAD software and will carry out strict review during the drawing process. In the subsequent metal manufacturing process, we will also insist on the implementation of product quality testing.

One-stop Shop

We are committed to providing customers with comprehensive custom metal fabrication services to meet your project needs, saving you time, money and effort. Not just AutoCAD detailing, we also have various services such as laser cutting, welding, forming, etc.

Auto CAD detailing FAQ

We can provide you with free quotation service as soon as possible within a few hours, just need you to upload design drawings and detailed technical specifications easily.

In order to ensure that the quality of products can meet the strict requirements of customers, our professional team first reviews and confirms the feasibility of design, and then puts it into subsequent production. From the selection of raw materials to product fabrication, we will use professional equipment to test the quality of parts with international standards in every link.

Our delivery time is short. After confirming the order, we will manufacture the required metal parts for your project as soon as possible, which will be delivered in about two to eight weeks, most of the time will be in transit.

more customer reviews

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.