Laser Cutting Service

首页 » Metal Fabrication Services » Laser Cutting Service

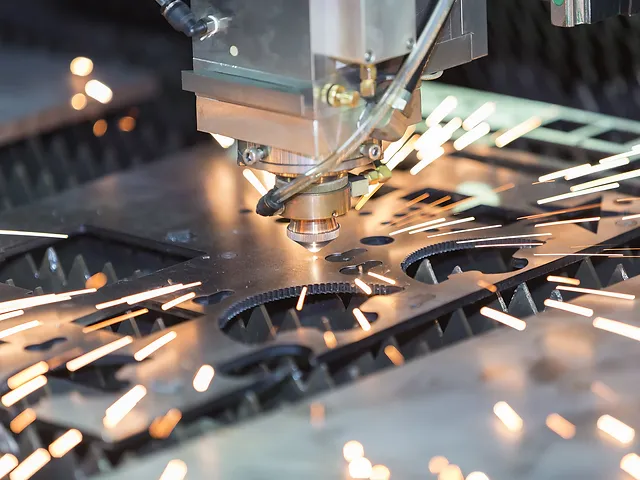

Laser Cutting Services

RFS has always insisted on providing customers with first-class laser cutting services and satisfactory customized metal fabrication solutions for over decades. At RFS, in the laser cutting process, our experienced engineers manipulate the computer to guide the advanced high-powered lasers to cut the desired shape from materials such as stainless steel.

In addition, we not only provide you the best cutting quality of your products, but also provide professional optimization suggestions for your design scheme. Contact us, it is an ideal choice for you who working with thinner, more demanding and more complex materials, let us handle the customized metal fabrication in our ISO 9001: 2015 certified factory.

What is Laser Cutting

Laser Cutting refers to the precise cutting of metal and other sheet materials with laser, which is achieved by applying the high power density energy generated after focused laser light. Therefore, Laser Cutting parts can be machined with high accuracy and efficiency. It is a general tool for rapid prototyping and small volume forming.

Benefits of Laser Cutting

Compared with the traditional sheet materials processing method, Laser Cutting, as a popular modern process, has various advantages, as described below.

1. High Precision & Effective Productivity

2. Good Cutting Quality

3. No Mold Investment & Lower Production Cost

4. Low Subsequent Maintenance Cost & High Cost Performance

5. Multiple Types of Cutting Materials

1. High Precision & Effective Productivity

Laser cutting process has the characteristics of precision, flexibility and efficiency. The machine is generally equipped with multiple CNC worktables. During operation, it is only necessary to change the CNC program, then it can be applied to the cutting of different shapes of parts with tight tolerance according to your needs, which helps to directly shorten the product processing and manufacturing cycle, and effectively improve productivity.

2. Good Cutting Quality

The laser cutting machine makes use of the characteristics of laser non-contact processing, does not damage the workpiece, the cutting surface is smooth and beautiful, and the processed products are of good quality and basically without burrs, which can save additional work steps and costs.

3. No Mold Investment & Lower Production Cost

Laser cutting machine can directly process various hardware workpieces without mold, thus there is no mold consumption, no need to repair and replace the mold, which can save processing costs and reducing production costs.

4. Low Subsequent Maintenance Cost & High Cost Performance

The laser cutting machine has stable performance. It is durable and not easy to be damaged. Besides, the machine can work continuously, and has great advantages in the later maintenance cost.

5. Multiple Types of Cutting Materials

As a precise processing method, laser cutting can cut almost all materials. Its cutting ability is not affected by the hardness of the cut material. The main categories of the cut materials include metal, non-metal, metal matrix and non-metal matrix composites, leather, wood and fiber, etc.

Selection of raw materials

Commonly cutting materials include steel, stainless steel, carbon steel, galvanized steel, copper, aluminum, titanium and other metal materials.

Advantages of our services

Quick Quotation

RFS provides you with free and fast quotation services. As long as you contact us and upload your drawings, you will receive specific plans and quotation feedback from professionals for your orders usually within a few hours.

Rapid Lead Time

After we confirm the order, advanced machines, professional team and efficient execution will enable your products to be delivered to you as fast as possible, usually two to eight weeks. The specific time depends on the complexity of your project. The delivery time of the product is usually stated to you together with the quotation.

One-stop Shop

RFS is committed to being a one-stop shop for your sheet metal projects that serves you to custom almost all parts in one place, helping you avoid wasting time and resources.

Decades of Manufacturing Experience

RFS has been specializing in metal fabrication services for more than 20 years. We are absolutely qualified that we can meet your strict requirements for products, which also makes us a leading manufacturer in the same industry.

Full Inspection System

RFS is equipped with comprehensive and advanced quality inspection equipment. Every step of production must go through strict quality inspection and testing to meet your requirements and exceed your expectations.

Professional Team

Our team is all experienced professionals. After receiving your order and plan, our engineers will provide you with the optimized design scheme of the project for your reference according to the actual situation.

Laser Cutting FAQ

Laser cutting is a thermal separation process. The laser beam hits the surface of the material and heats it to the point of melting or complete vaporization. The laser cutter follows the geometry set by the computer, separating the desired shape during the process.

Yes. We stock extensive materials, there are more than 300 distinct materials to fulfill your needs.

Unfortunately not. Please send your 2D, 3D, PDF or CAD drawings to us, we will offer the manufacturing design review and optimization after received your order.

It is also acceptable for a small order volume. There is no MOQ requirement here. We pride ourselves on treating customers with different orders equally.

more customer reviews

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.